We offer turn-key custom made lithium battery packs for your business

At Lithium Power, Inc., we take pride in our team of professional engineers who are experts in engineering and manufacturing custom lithium batteries and battery systems ideally suited for various industries and applications. Whether you are in the automotive sector (non-propulsion), renewable energy storage field, medical industry, autonomous robotics space, or looking for a lead acid replacement solution, we have you covered. Our engineers will work closely with you to analyze your power requirements and propose technical specifications, instilling confidence in the precision and reliability of our solutions.

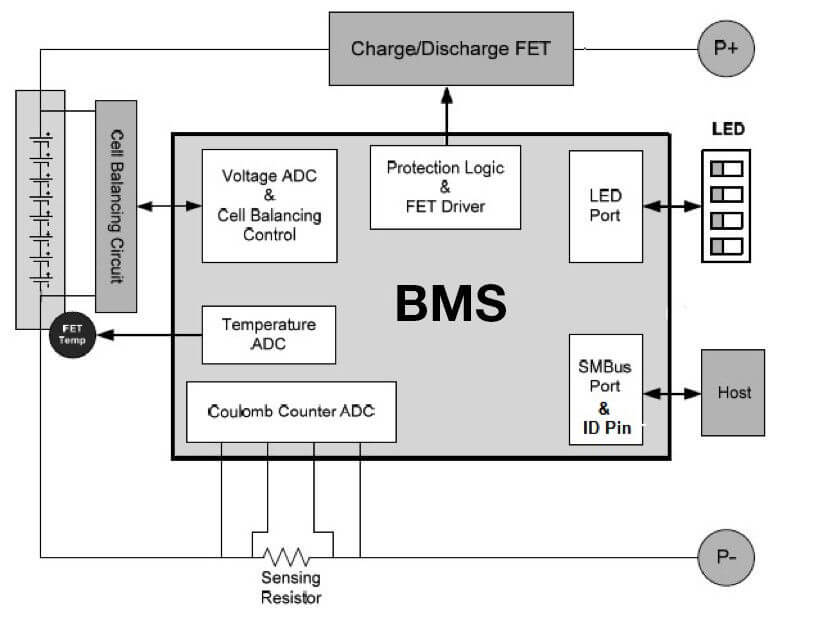

We promise to design the most optimal solution meeting your unique needs of charge and discharge rates, dimensions, weight, operating temperature range, programmability, cycle life, scalability, efficiency, and cost. We take care of the complete package, from cell selection to implementing our proprietary BMS, IP-rated enclosure tooling, various communication protocols, custom paired chargers, certifications, and door-to-door delivery service. We pay meticulous attention to details, ensuring our custom batteries not only meet but exceed your expectations. Our focus on seamless integration into your system or device ensures compatibility and performance, empowering your innovation and giving you the confidence to push the boundaries of your industry.