Recycling Lead-Acid Batteries

Lithium-ion batteries are the industry’s favorite, driven by consumer demand, and have become the number one choice over the past few years. However, when it comes to battery recycling globally, lithium-ion batteries are nowhere near the success story of time-proven and reliable Lead-acid batteries that have become one of the most recycled consumer products worldwide.

Lead-Acid Battery Recycling Facts:

- In many regions, approximately 99% of lead-acid batteries are recycled, making them the most successfully recycled battery type.

- Around 80% of a new lead-acid battery comprises recycled materials, including lead, plastic, and sulfuric acid.

- Lead-acid battery recycling processes recover up to 96-98% of lead, reducing the need for virgin lead mining and conserving resources.

- By recycling, nearly 1.7 million metric tons of lead are reused annually, significantly lowering greenhouse gas emissions and waste.

- Many countries, including the U.S. and the EU, have stringent regulations ensuring lead-acid battery recycling through take-back programs and manufacturer accountability.

So how can we follow this model with Li-ion batteries?

Well, the story for lithium batteries is not so simple.

- Li-ion batteries are far more complex and contain many potentially valuable components such as Lithium, Cobalt, Nickel, Copper, Manganese, and Aluminum.

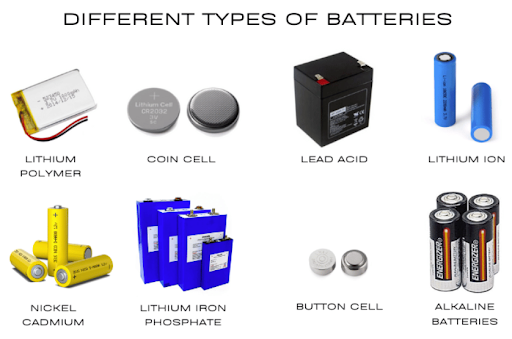

- Batteries vary in size from small buttons to sizeable electric vehicle packs.

- Li-ion batteries are not designed to be recycled and often contain adhesives, plastics, and welded materials that are difficult to disassemble.

- There are too few recycling companies to handle the volume and economies of recycling. The market is immature and lacks the technology and scale to deliver success.

Due to economics, current battery recycling processes typically recover only certain metals for reuse. Lithium Iron Phosphate batteries are commonly not recycled because the only valuable metal is lithium.

The standard methodology is:

- Discharge the battery to prevent risks of fire or explosion during processing.

- Manually dismantle the batteries to separate components like the casing, wiring, and current collectors (copper and aluminum).

- Shred the battery material to form, commonly called ‘black mass’, and sent it onward for specialized processing, such as pyrometallurgy and hydrometallurgy, to extract the valuable materials.

Some key innovations include:

- Direct Recycling, which retains more battery materials in usable condition.

- Bioleaching (Microbial Recycling) is where microorganisms like bacteria or fungi extract metals by producing organic acids.

- Electrode-to-electrode recycling directly converts used electrodes into new electrodes with minimal reprocessing.

- Ultrasonic Recycling, where ultrasound waves are used to remove valuable coatings (e.g., cathode material) from battery foils.

These novel recycling methods aim to make lithium-ion battery recycling more sustainable, scalable, and cost-effective, supporting the growing demand for eco-friendly energy storage solutions.

Custom Made Batteries Designed for End of Life Battery Recycling

At Lithium Power Inc., we prioritize the environment. All our custom-designed batteries are engineered with end-of-life in mind. We rely on good partners from the industry to help us with our recycling journey.

We thank Lesley Blaine, co-founder of Collaborative Engineering Services for this overview of repurposing and reusing batteries. CES works with companies to ensure battery assets are fully utilized and have a profitable end of life. For more information, please email: info@collaborativeengineeringservices.uk